The problem

MOHOC saw an opportunity to design an action camera that could meet the high expectations and requirements of the military’s special forces in order to help them improve safety and monitoring during dangerous missions. MOHOC were experts in this market but needed help to design and manufacture this camera from the ground-up.

The Q Design solution

Q Design’s role was to drive the overall program and system integration of the product from concept to production. The team developed the mechanical engineering design, sourced and managed the supply chain, led the development of custom optics, and worked with partners and vendors on the complete system integration and manufacturing.

The problem

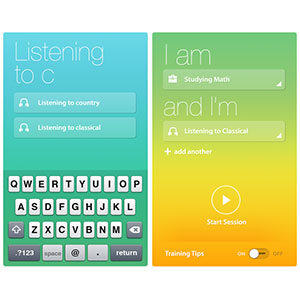

Melon was one of the earliest innovators in the wearable space having developed a consumer EEG headband to monitor brain activity and apply neuroscience to understand how to use that data to improve wellness. The company had developed an early proof-of-concept, but needed a team to help engineer and manufacture a final product ready for the consumer market.

The Q Design solution

Q Design led the complete engineering of the headband, set up the supply chain, and oversaw the entire tooling, manufacturing and test processes until mass production. Melon was subsequently acquired shortly after launching the product.

The problem

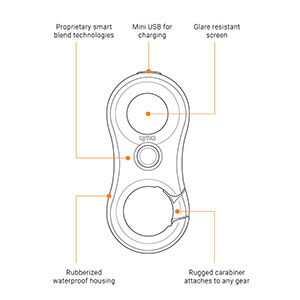

Lynq wanted to launch its low power, long range smart compass for the consumer market and needed local support in China to work closely with its manufacturing partner to complete the NPI process.

The Q Design solution

Q Design provided the “boots-on-the-ground” resources to help manage the final stage of the NPI process and launch the product successfully.

The problem

Lee Kum Kee wanted to address food safety concerns and promote sustainability by developing a home hydroponics system to enable consumers to grow their own healthy food.

The Q Design solution

Q Design led the program to fully design, engineer and prototype the home hydroponics system into a “looks like, works like” functional prototype read for manufacturing.

The problem

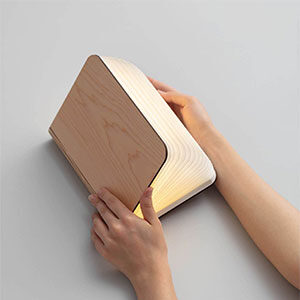

Like many young hardware startups that outsourced manufacturing in China, Lumio needed a trusted partner that could provide on-site support at their factory to oversee the manufacturing and quality control of the finished product.

The Q Design solution

Q Design provided “boots-on-the-ground” resources to work closely with the factory partner and key suppliers to achieve the production yield, quality and output that Lumio required to fulfill its production orders and schedule.

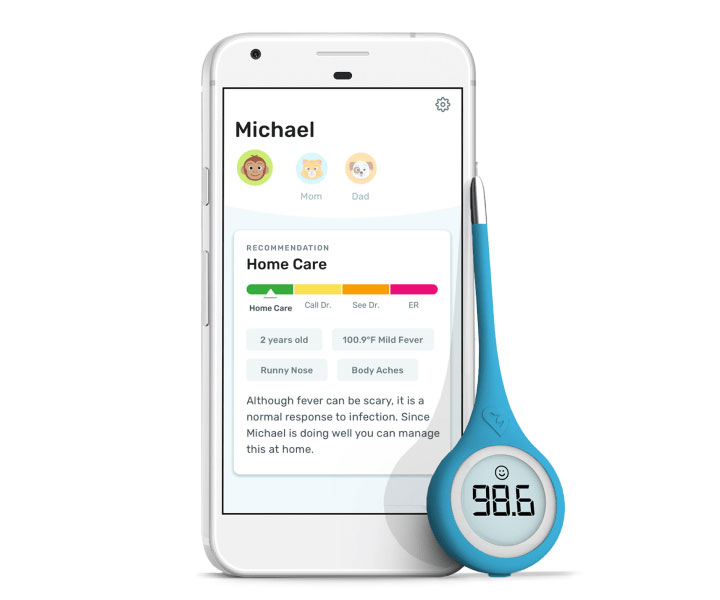

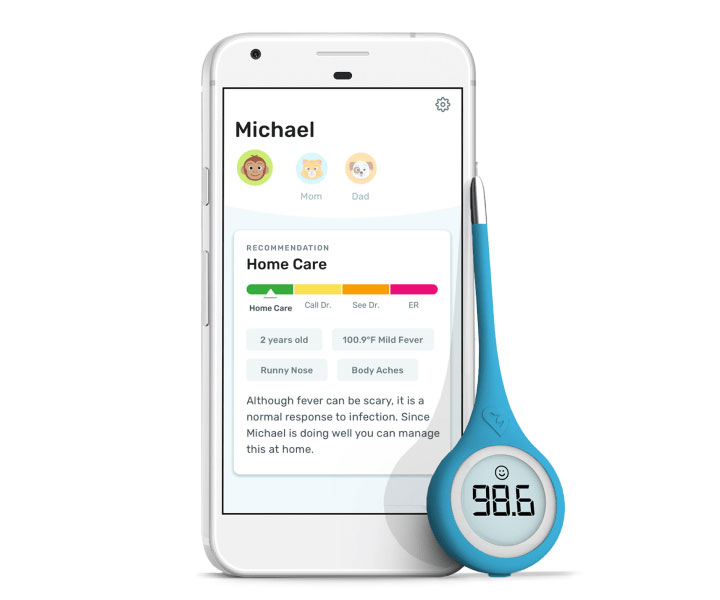

The problem

Kinsa Health needed local resources to support the manufacturing of its smart thermometers and provide the daily on-site collaboration with its factory partners.

The Q Design solution

Q Design worked with Kinsa Health and its factory partners during the manufacturing NPI stages to support the development of both the oral thermometer and infrared thermometer.

The problem

Insight Robotics developed an AI-assisted early fire detection system for forestry management and was initially hand-assembling units in their workshop, but needed to transfer and source the production to a contract manufacturer in order to scale up the business.

The Q Design solution

Q Design sourced, setup and managed a contract manufacturer that could handle the complex assembly and testing of the product, ensuring that there would be a reliable and cost-effective factory.

The problem

Headspin developed a convertible and modular lighting system for outdoor use and needed help to transform the initial prototype into a production ready design then source and oversee the manufacturing of the product.

The Q Design solution

Q Design led a full program to engineer the product and then source and manage the tooling and manufacturing of the product.

The problem

Gate Labs needed engineering support and local resources to work with its manufacturing partner to complete the manufacturing NPI process and start production.

The Q Design solution

Q Design provided the on-site resources and support to work closely with the factory and tooling vendor throughout the NPI stages to build and launch the product.

The problem

Firefly wanted to develop a sleek, portable electronic vaporizer for the growing market in the U.S. and needed help with designing and manufacturing the product.

The Q Design solution

We worked with the Firefly team on a complete end-to-end project starting with just a concept sketch. Our team led the full engineering, prototyping, manufacturing and quality inspection of the product.