The technology

Ambiq manufactures microprocessors with an ultra-low power design that enables battery-powered endpoint devices to operate better and last longer. They offer total system advantage over energy efficiency on the chip to run sensing, data storage, analysis, inference, and communications within ~1mW.

The impact

Ambiq represents a quantum leap forward in ultra-low power design that provides the most energy-efficient sensor processing solutions on the market. Their technology has already delivered superb energy efficiency in a wide range of applications, such as brain sensing headband, safety device for your kids; a multi-function smartwatch that can last for up to 21 days on one charge; a smart ring to help track vitals 24/7 for contact-tracing in the pandemic era.

The opportunity

For the 50 billion IoT devices to be deployed in the next 5 years, energy efficiency remains the key challenge. Ambiq has proven its products to be much more powerful than any other existing substitutes in the market and will be a major driving force behind the IoT revolution.

The icing on the cake

Q Capital has collaborated with Ambiq in designing in its technology with new customers in new verticals and markets.

The technology

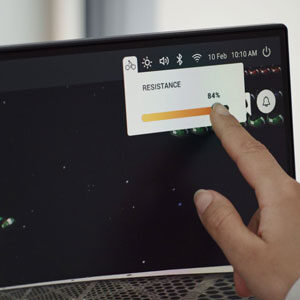

StrongArm’s FUSE Sensor is a next generation IoT device engineered to provide real-time, accurate safety data. Each data point contributes raw input to AI-based algorithm calculations and actionable recommendations delivered via a real-time dashboard.

The impact

WalMart began rolling out StrongArm’s FUSE platform since 2018, across 18-buildings and 6,000 associates. The latest data showed that StrongArm has driven targeted injury reduction of more than 64%. StrongArm is instrumental in creating a safe work environment such that each Industrial Athelete at Walmart can get home safely every day.

The opportunity

Logistics and warehouse management has experienced tremendous growth in the past few years, and such high growth is likely to continue due to explosion in ecommerce. Providing a safe work environment is an absolute must for operators to recruit and retain any warehouse associates.

The icing on the cake

Q Capital, with Q Design, is helping StrongArm develop their second-generation product and scale up their product volume with our manufacturing resources in Asia.

The problem

Fitbit was the earliest innovator in designing and developing Bluetooth-enabled health trackers before “wearables” was even known as a product category. Designing and manufacturing miniaturized consumer devices that were comfortable and easy-to-use required new materials and manufacturing processes that didn’t yet exist.

The Q Design solution

Our team worked closely with Fitbit’s internal team to implement the industrial design into a manufacturable mechanical design by collaborating with the contract manufacturer and tooling vendors and then supporting the tooling and production of the devices. Q Design worked with Fitbit for over 6 years to develop and manufacture 5 generations of wearables including the One, Zip, Flex, Surge and Blaze plus the first wireless scale, Aria.

The technology

Elementary’s easy-to-use software, deep learning AI, and camera systems are built to capture visual data, deliver fast and reliable real-time judgements, and provide lasting value to any business.

The impact

Elementary designs automation products with a human-in-the-loop approach that improves working conditions while delivering maximum results. Their products push quality, traceability, and root cause analyses forward, which in turn makes manufacturing more efficient and less wasteful.

The opportunity

Leveraging expertise in machine learning, artificial intelligence, and computer vision; Elementary is pushing the limit of automation being used in the manufacturing PCB boards, consumer products, automotive and beyond.

The icing on the cake

Q Capital is working with Elementary to identify potential customers in the manufacturing sectors in Asia.

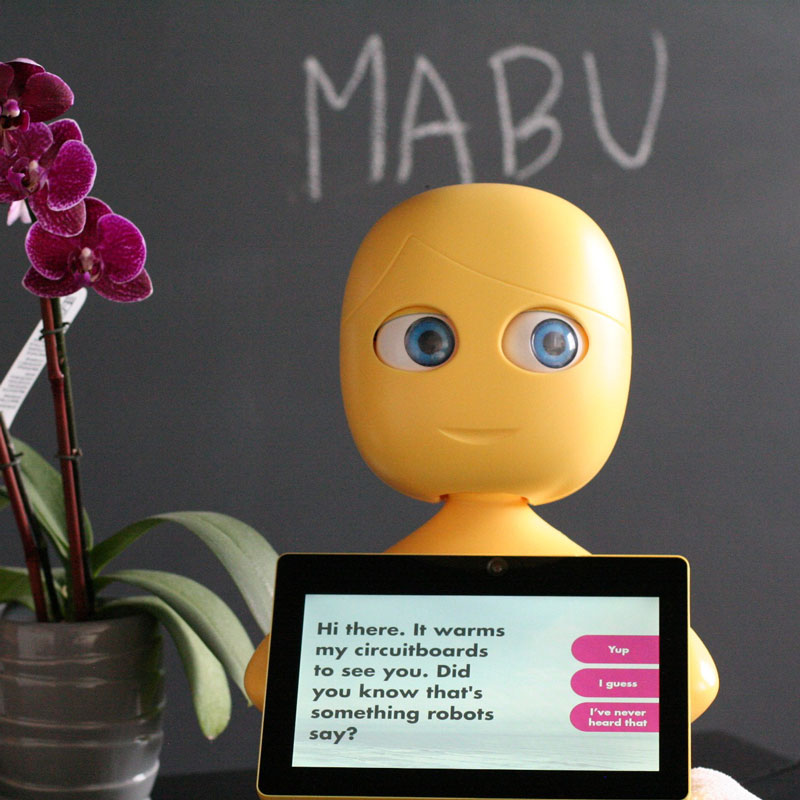

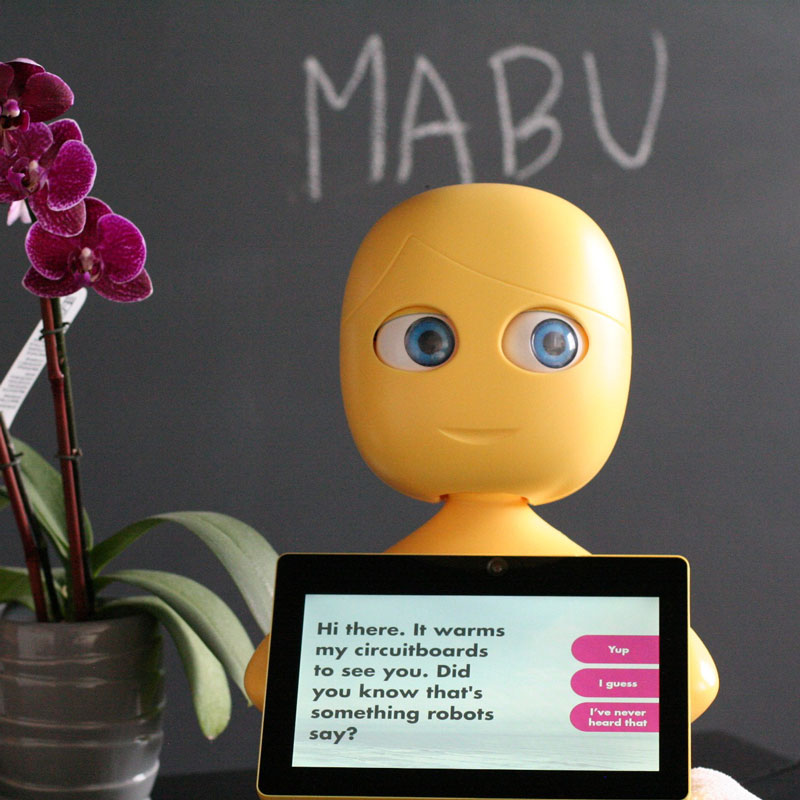

The problem

Catalia Health developed a robotic system that was initially hand-assembled in small quantities at their workshop to support early customer pilots and testing. As the company grew, it needed to develop a reliable and robust manufacturing process and supply chain to support larger customer orders while maintaining quality and optimizing costs.

The Q Design solution

We worked closely with Catalia Health to source a high-quality contract manufacturer in China that could meet their requirements of cost, quality and capacity. Q Design then led the program to fabricate new tooling, setup the production line and implement quality control processes to create a reliable and robust production line. With our local team in China, we provided on-site and on-going manufacturing and quality support and removed the worries of overseas manufacturing so that Catalia Health could focus on its core business.

The icing on the cake

Q Design eventually referred Catalia Health to Q Capital, which made an early-stage investment into the company. We also continued to collaborate on the engineering and manufacturing of the next generation robot in a follow-up project.

The problem

Playpulse developed an innovative stationary bike that combined exercise with interactive 3D gaming for consumers of all ages. The bike, however, was an early prototype that was not ready for manufacturing as a consumer product and needed a complete design overhaul.

The Q Design solution

Our team worked with Playpulse and the Industrial Design partner to completely redesign the bike from scratch and develop a sleek new model that would appeal to consumers and fit beautifully into the home. Q Design led the engineering, prototyping and manufacturing of the bike and worked with the CM for production.

The icing on the cake

Q Design helped Playpulse raise funding in its Seed Round and has a position on its Board of Directors to help steer the strategy of the company.

The problem

Unagi was sourcing its electric scooter from China but needed a local team to work closely with their manufacturing partner to oversee the production, monitor quality, and improve the overall yield. There were large communication gaps and delays which made production management even more challenging.

The Q Design solution

Our team provided the “boots-on-the-ground” resources to step-in and work closely with the factory on a daily basis to resolve open issues and develop the plan and processes to improve production yield, quality and output. This helped Unagi meet its growing sales demand.

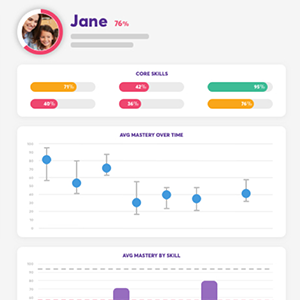

The problem

Square Panda developed a wireless playset that paired with a tablet to help children progressively develop reading skills through the combination of tactile letters and adaptive digital games. They had built a prototype, but needed help to complete the DFM, tooling and manufacturing of the product.

The Q Design solution

Q Design worked closely with Square Panda and supported the mechanical engineering, DFM, sourcing, tooling, and manufacturing of the playset.

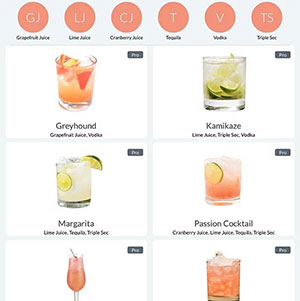

The problem

Somabar developed a fully automated bartending system that could mix hundreds of cocktails and be sold to consumers as well as businesses. They need a partner to take over the prototype design and help re-engineer it for manufacturability and then source and manage a manufacturing partner to produce it.

The Q Design solution

Q Design led the prototyping, mechanical engineering, electrical engineering, tooling, testing and manufacturing of the product.

The problem

Nomiku invented a new kitchen appliance to bring sous vide cooking into the home for consumers and needed a partner to transform their early prototype into a manufacturable product and work with a factory to build it.

The Q Design solution

We worked with Nomiku to improve their design for mass production with a focus on safety, reliability and durability in a kitchen environment. Q Design also sourced the manufacturer and oversaw the entire tooling, manufacturing and testing process.